DMC has a long history of successfully executing complex motion control projects. From dedicated multi-axis motion controllers to integrated motion control using technology PLCs to intelligent conveyance systems, DMC’s motion experts can handle the most challenging of applications.

Our team of engineers can support motion projects in many ways, from full project development to filling an internal technology gap, depending our your needs.

DMC’s Motion Control Services

From basic motion concepts to dozens of coordinated axis and motions profiles, our engineers have experience developing motion applications for systems of all sizes. Our wide range of industry experience has provided us opportunities to become experts in both general and industry specific motion solutions.

DMC’s Motion Control Programming Services and Servo Application experience include:

Electronic Camming

Electronic Gearing

Precision Pick & Place

Multi-Axis Coordinated Motion

PID Tuning

Data Collection

Vision Integration

Flying Cutoff

Hydraulic Servos

Printing and Registration

High-speed Printing

Web Handling

DMC’s Motion Controller Platform Experience

As technology experts, our motion control programmers work with multiple motion control platforms. That knowledge allows us to select and recommend the right platform for an application or to support our clients using their preferred hardware platform or software stack. Some of DMC’s motion controller platform experience includes:

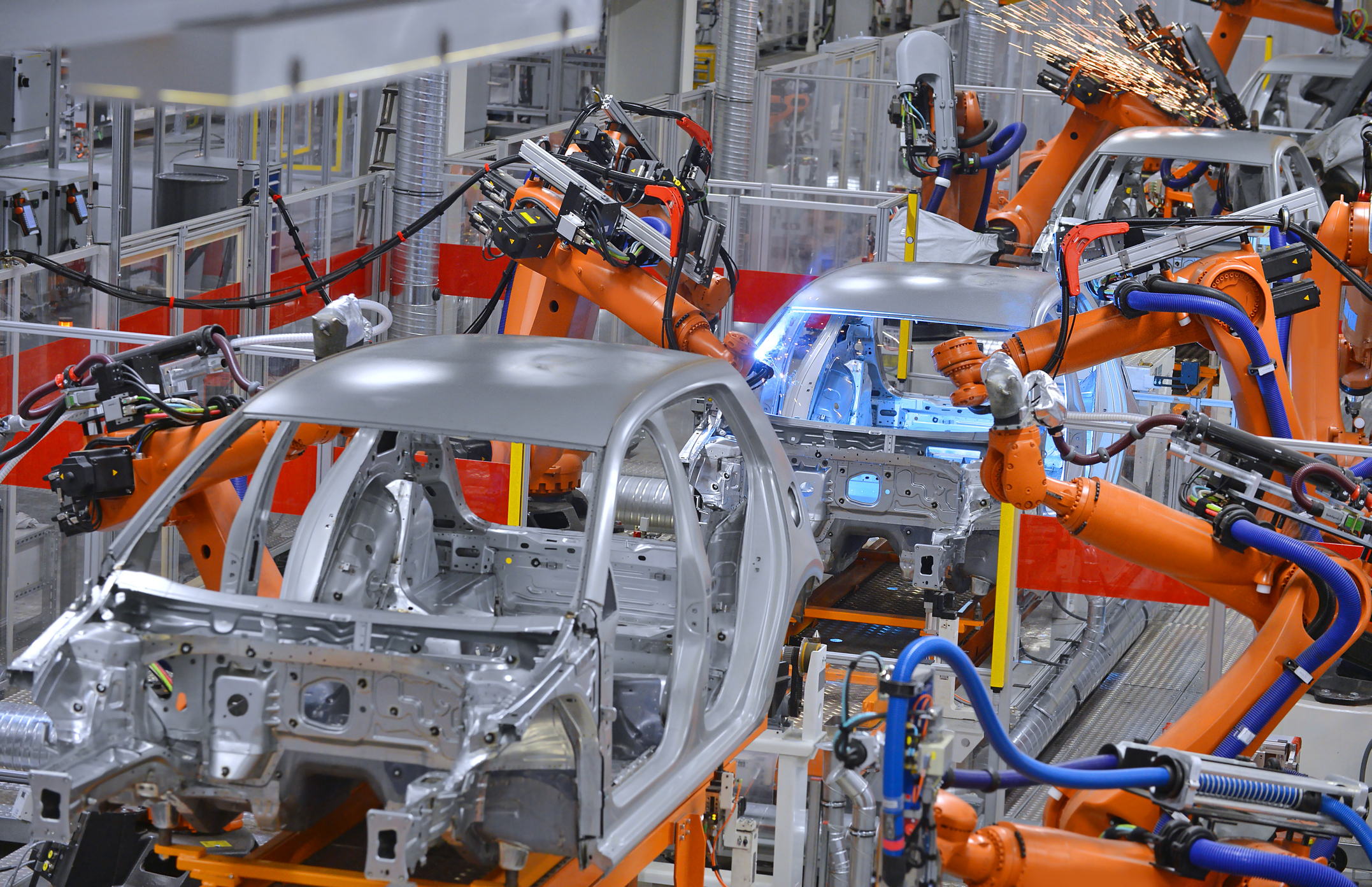

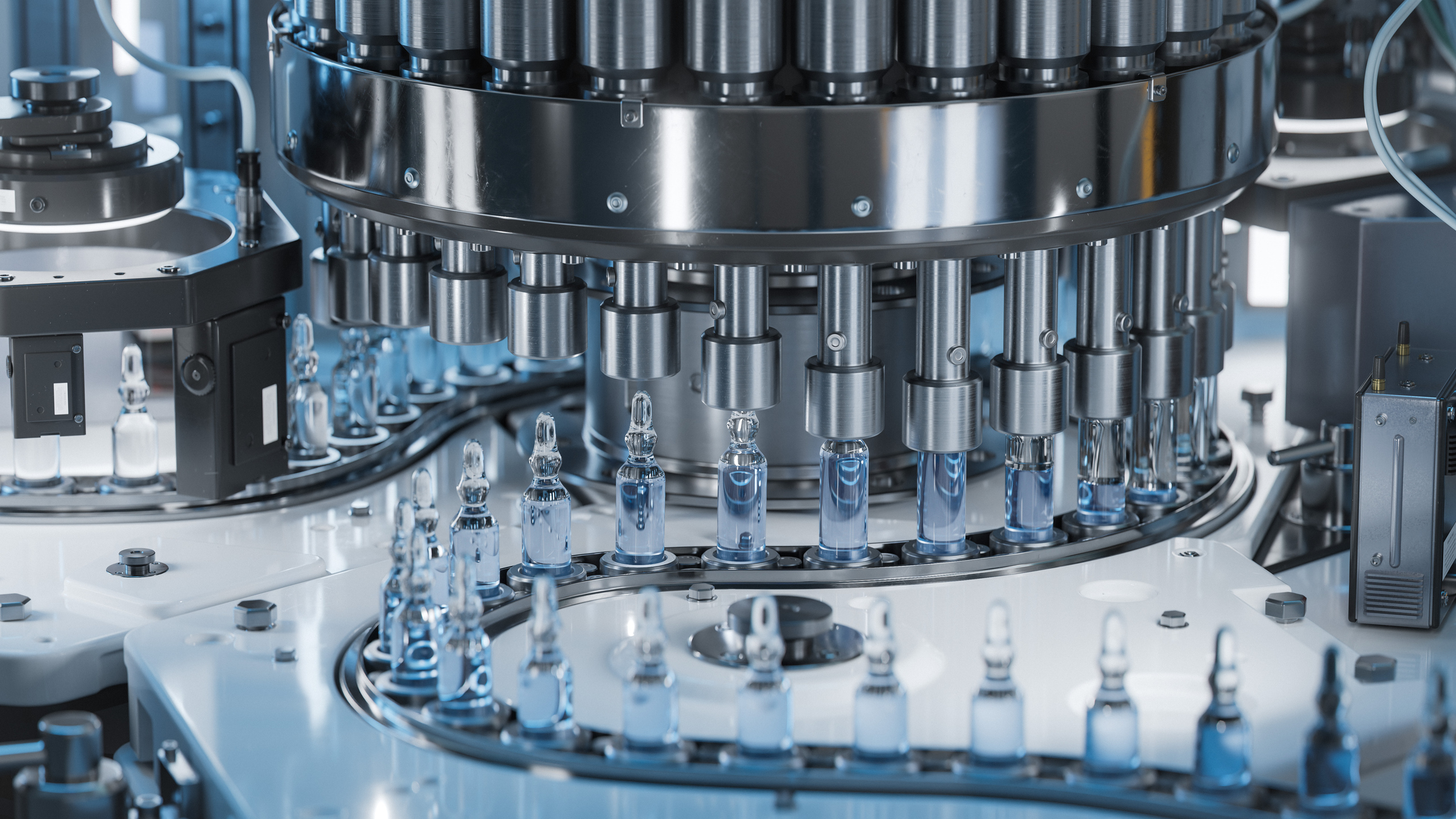

Industry Experience

DMC has a proven track record across a wide range of industries.

FAQs

What is Motion Control?

Typical Motion Control Systems and Servo Systems involve one or more motors providing feedback (typically through an encoder) to a programmable motion controller. The servo targets one or more command parameters (position, velocity, or torque) through PID control loops. Modern Motion Control Systems are capable of sophisticated applications, such as several electronically geared axes, camming, high-speed motion, and precision positioning. Many modern motion control platforms employ high-speed synchronous communication buses, such as EtherNet/IP, POWERLINK, EtherCat, PROFINET, or Drive-Cliq, allowing simple integration of advanced feedback devices like multi-turn absolute encoders.

What are the benefits of a properly tuned system?

Properly tuned systems and optimized motion control programs are essential for achieving peak performance in automated systems. A skilled motion control engineer ensures that servo motors, drives, and control loops are precisely calibrated, resulting in faster response times, minimal overshoot, and smoother operation.

By working with experienced motion control companies like DMC, manufacturers can fine-tune their systems to minimize inefficiencies, reduce mechanical wear, and enhance overall system reliability. Investing in expert motion control engineering leads to significant improvements in cycle time, throughput, and less product waste; ultimately boosting productivity and operational efficiency.

What is it like working with DMC?

Motion Control plays a key role in modern industrial automation systems. From precise positioning, electronic synchronization between motors, or execution of motion profiles, motion controller is at the heart of some of the most complex machine control applications. It can also be a technology that requires a significant amount of training, experience, and knowledge in master.

DMC’s talented team of engineers bring decades of experience in designing, programming, and commissioning complex motion control systems. We are able to help clients fill that experience gap in order to ensure success.