Ensuring a Quality Product

Knowing the status, location, and history of any part moving through a facility is essential to maintaining and proving the quality of products that get delivered to customers. As a leading manufacturing automation and system integration solutions provider, DMC helps companies track and provide traceability to operations and products to ensure that quality product is delivered every time.

Ready to start your next project?

Platforms & Technologies

Our experienced engineers undergo continuous training in leading industry tools. DMC implements Track & Trace solutions from:

- SIMATIC IT/OpCenter Unified Architecture

- Wonderware MES/Performance

- Sepasoft Track and Trace built on Ignition

- Custom MES solutions

Track & Trace Features

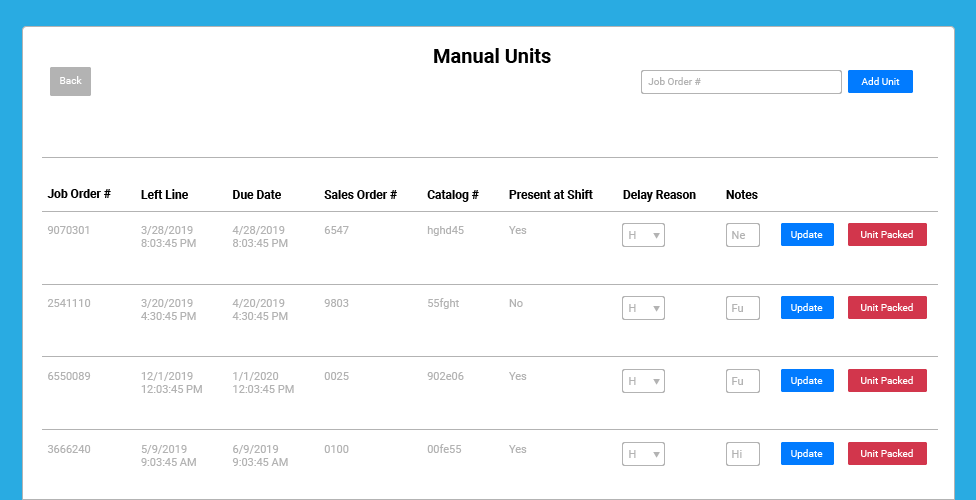

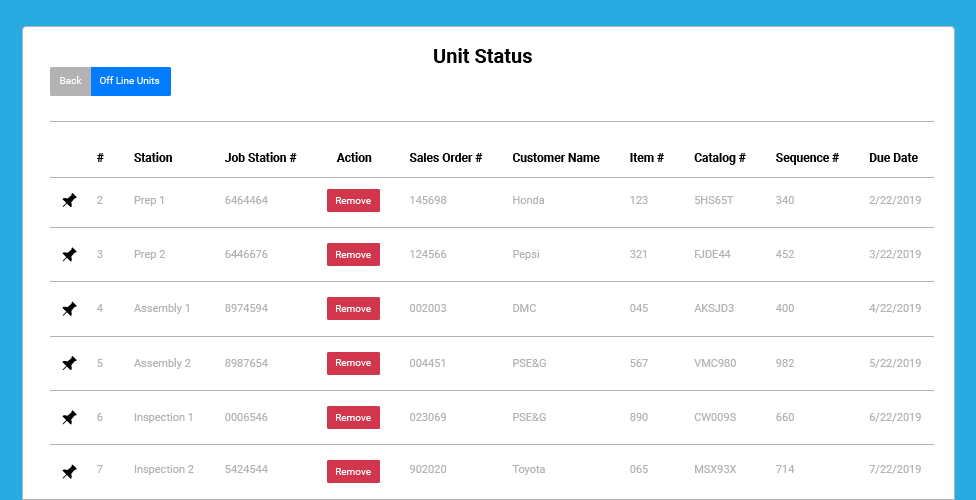

We’ve developed solutions that provide the following track & trace functionality:

- Barcode, RFID, and visual part identification

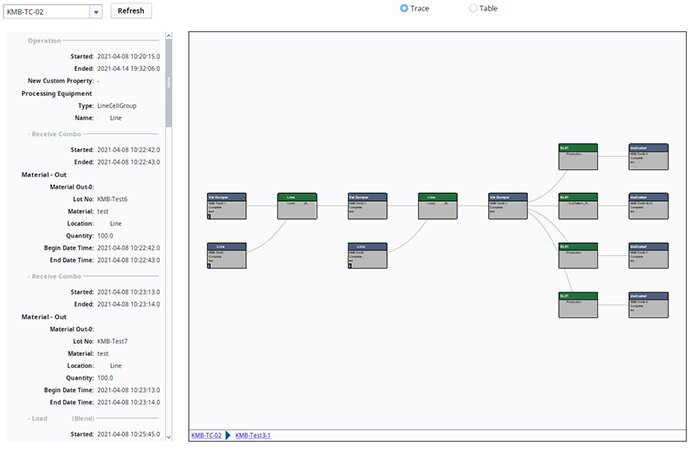

- Product Genealogy and Lot Traceability

- Electronic Work Instructions, Quality Records, and Signatures

- Rework and reject tracking

- Automated equipment data logging for process and/or discrete data

- Real-Time location

- Time in process

- Vision Inspections

- Bill of Materials (BOM) / Bill of Process (BOP) Tracking

- Integration to ERP, Warehouse, and other business systems

- Integration to PLC, SCADA, and other shop floor systems

Data Visualization & Reporting

Make informed decisions with your data. Analyze key performance metrics such as work in process, part history/genealogy, quality, and throughput using the following data visualization tools:

- Standard platform reports

- Custom reporting using tools like SQL Server Reporting Services

- Web and mobile dashboards

- Data export to MS Excel

- Logging results to database

- Send information to ERP and other business systems

- Configurable alert emails and/or text messaging