Manufacturing Automation & Intelligence

Engineering intelligent factory floor systems, including electrical & mechanical design and build;

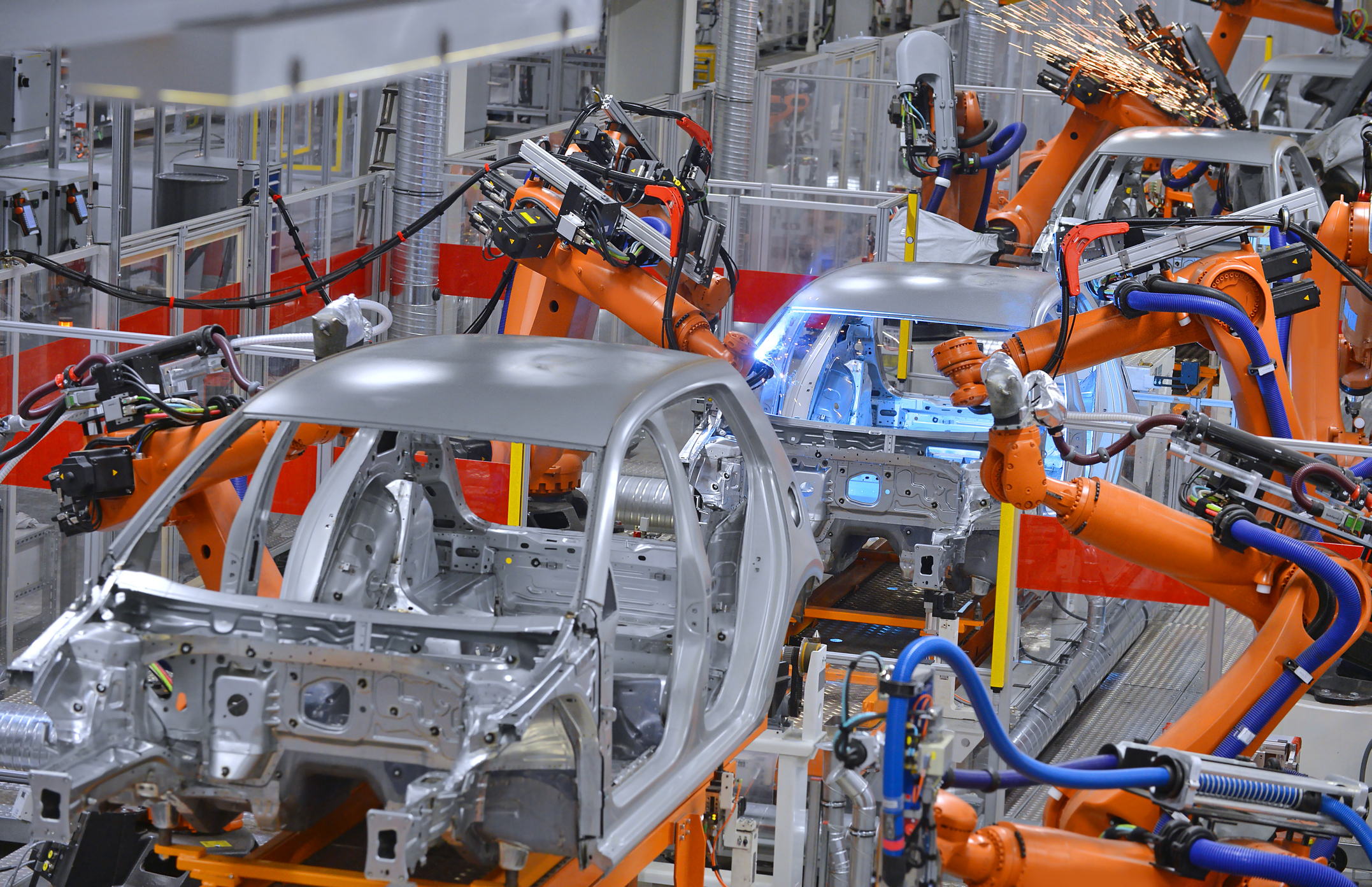

PLC, SCADA, MES, and robotics programming

Industrial Automation Systems

DMC is a trusted leader in the automation industry, delivering advanced industrial automation systems and integration services to clients worldwide. We offer a full range of services, including controls and software engineering, panel design & fabrication, system integration, and commissioning.

With deep expertise across all levels of industry automation—from cloud-based MES and OEE systems to plant floor PLC control—DMC helps clients adopt the right technologies to stay competitive in the evolving automation industry.

We support our clients in a wide variety of ways, including:

Upfront Controls Engineering

Design and documentation of controls systems including development of functional specifications and detailed software design documents, hardware and software selection, and machine safety analysis.

Automation Programming Services

PLC, HMI, SCADA, MES, Motion Control, Machine Vision, and Robotics programming.

Onsite Services

Service calls and troubleshooting, IO checkout, commissioning, and production support.

Automation Project Management

Hands-on project management, from design through project completion.

Turnkey Automation Systems

End-to-end turnkey solutions from concept to start-up.

Ready to start your next project? We can help.

Industry Credentials

DMC holds several key industry credentials with leading technology providers.

Automation & Controls Engineering

DMC offers a full range of automation services, leveraging modern technology to design, develop, and deliver advanced automation systems.

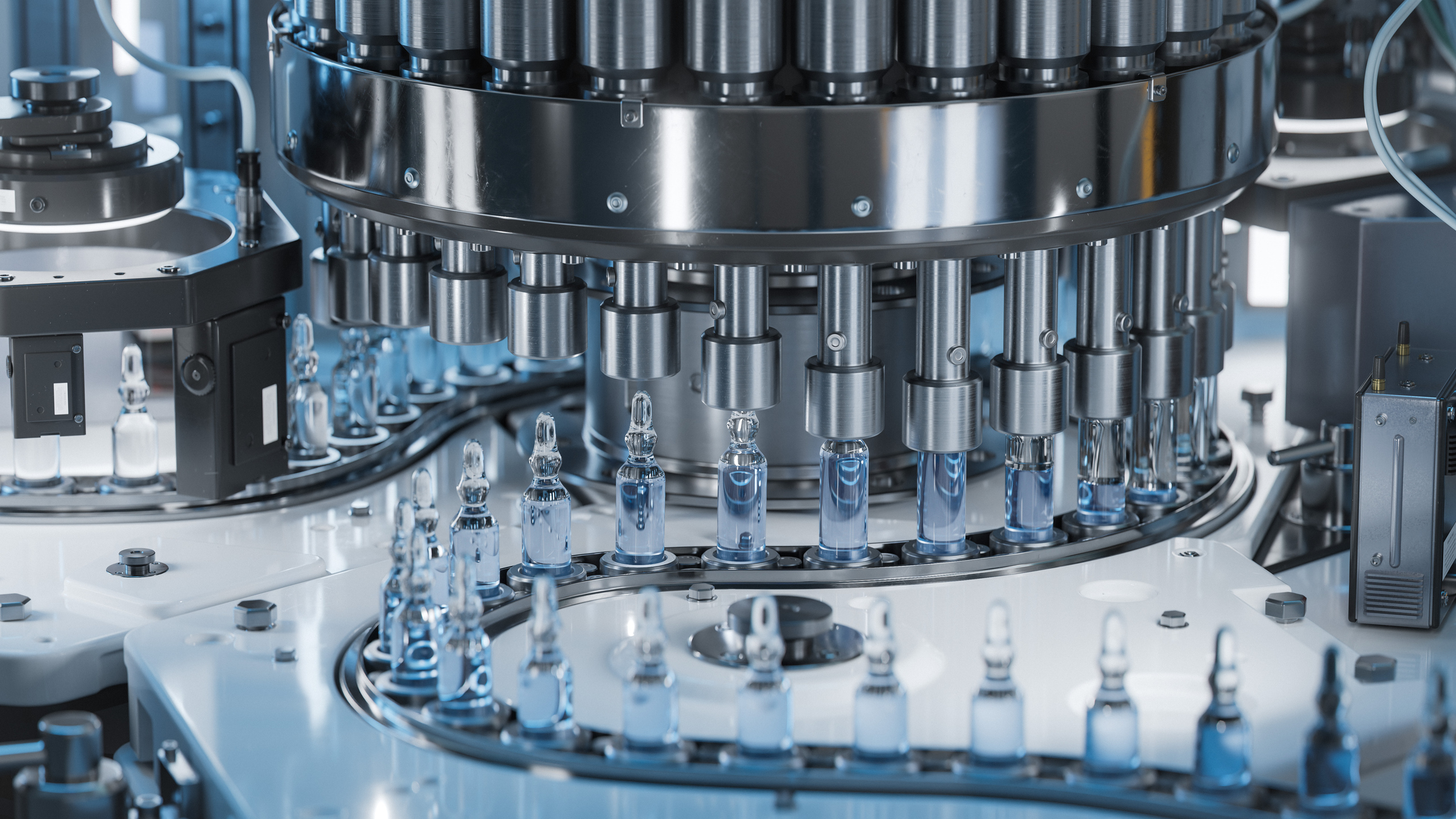

Industry Experience

DMC has a proven track record across a wide range of industries.

Technical Flexibility

DMC’s complementary service offerings allow for cross-platform solutions and tight integration with non-traditional automation systems

FAQs

What is Industrial Automation?

Industrial automation is the use of technology to perform industrial tasks. It relies upon control systems (computer-based systems that execute control software) to automate processes and machinery using actuators, sensors, processors, and networks. Industry automation reduces human intervention, improves safety and reliability, enhances quality and efficiency, and provides better insight into business operations.

What role does robotics play in industrial automation systems?

Industrial robots play a key role in any industrial automation system and support a wide range of applications in manufacturing. Robots are used to automate repetitive manual tasks, including:

- Quality inspection

- Dispensing

- Assembly

- Machine tending, loading, and unloading

- Material handling (picking, packing, and palletizing)

How do smart factories enhance market responsiveness and adaptability?

By harnessing real-time data and connectivity, smart factories can optimize their manufacturing operations by reducing waste, improving efficiency, and enhancing product quality, ultimately leading to increased competitiveness in a rapidly evolving market.

Start Your Industrial Automation Systems Project

Looking to take your project to the next level?

Our engineers are eager to discuss your automation needs.

We’re Local

Get in touch with us to get started on your next project!