PLC Programming

DMC’s team of Automation Experts offer

PLC, HMI, and SCADA programming services.

PLC Programming Services

DMC has nearly three decades of experience implementing industrial automation solutions utilizing Programmable Logic Controllers (PLCs). Our engineers develop new PLC programs from the ground up and also troubleshoot, update, and add to pre-existing systems. We work with many industrial network protocols and hardware layers (PROFIBUS, PROFINET, Wireless PROFINET, Ethernet I/P, DeviceNet, Modbus, ModbusTCP, RS-232, RS-485, SERCOS, CAN, EtherCAT, and others).

We work with hardware from all major PLC manufactures and work with all of the most common industrial protocols (EtherNet/IP, Profinet, Profibus, EtherCAT, Modbus TCP, and others).

Legacy PLC Upgrade and Conversion Services

While some PLCs can last for decades, eventually everyone is faced with the need to upgrade and modernize their systems, especially when products are discontinued or have drastically increased prices. DMC offers PLC upgrade and system conversion services for a number of legacy controllers, including Allen-Bradley PLC-5, TI505, and Siemens S5 PLCs. Our engineers have extensive cross-platform experience with the Rockwell Automation ControlLogix/CompactLogix and Siemens S7 PLC series.

Customers who upgrade their systems enjoy such benefits as:

- Greater reliability

- Integration with modern MES and ERP systems

- Improved processes

- Easier system maintenance, modification, and expansion

- Improved access to service and replacement parts

- Full source code from DMC

Industry Solution Experts

PLC Programming

HMI and SCADA Programming

Motion Control Engineering & Servo Systems

Robotics

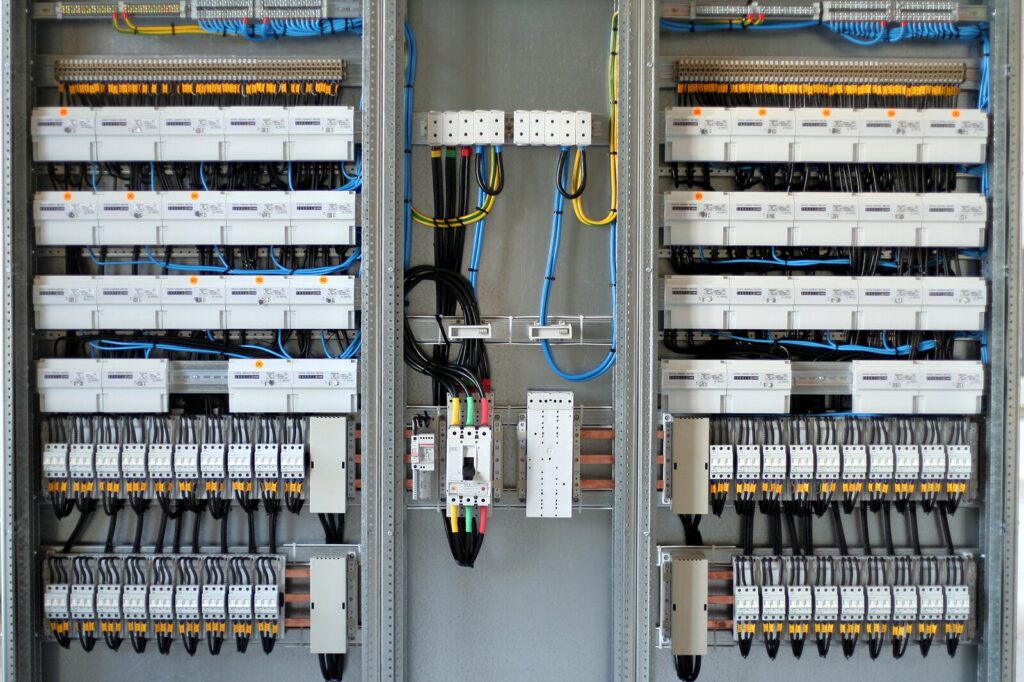

Control Panel Design & Fabrication

Extend Your Team

Under a tight timeline, or facing a challenging project? DMC’s experts can work as an extension of your team, providing as-needed support and collaborating with your internal staff.

We’re happy to train your team in best practices and system maintenance so they can take over once the project is delivered.

Tell us about your next project

Featured Case Studies

Why work with DMC?

3400+

Projects

Successfully completed thousands

of projects for customers

around the world.

250+ Experts

We are responsive, flexible, and often available to take large projects on–even with short notice.

Lastly, we believe customers should work with us because they want to, not because they have to. To that end, we build flexible systems, deliver full source code, and train your staff on system modification procedures.

Talk to one of our engineers about your project!

“DMC goes that extra mile to ensure that my needs are met. Having worked with other engineering companies in the past, DMC’s engineers and staff have proved to be a notch above the rest. The people at DMC are professional, intelligent, and easy to work with, and customer service is outstanding.”

– Paul Stechman, Bredemeier

Partnerships & Certifications

Wherever your team is in the process,

DMC can help.

Phone: (312) 872-0072

Email: email.sales@dmcinfo.com